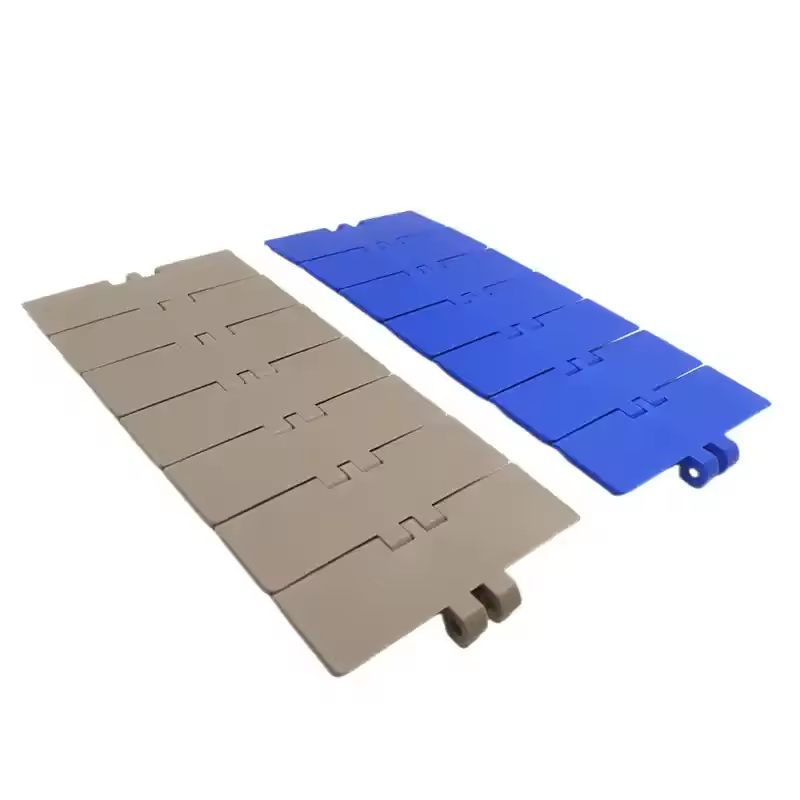

Plastic chain plates have emerged as a vital component in modern manufacturing industries, offering versatility, durability, and efficiency in material handling systems. Their lightweight nature combined with strength and resistance to corrosion makes them an attractive choice for various industrial applications. Unlike traditional metal conveyor systems, plastic chain plate provide smoother operation, reduce maintenance costs, and increase overall productivity.

Advantages of Plastic Chain Plates

Plastic chain plates bring multiple benefits to manufacturing processes. One of the most significant advantages is their corrosion resistance. In environments where moisture, chemicals, or extreme temperatures are present, plastic chain plates outperform metal alternatives that may rust or degrade over time. Additionally, plastic chain plates are lighter than metal, which reduces the energy required to operate conveyor systems. This translates into lower operational costs and improved energy efficiency.

Another key advantage is their flexibility and customization. Plastic chain plates can be molded into different shapes and sizes to fit specific manufacturing requirements. This adaptability allows manufacturers to design conveyor systems that are tailored to their production line needs. Furthermore, plastic chain plates operate quietly compared to metal chains, contributing to a safer and more comfortable working environment.

Applications in Food and Beverage Industry

The food and beverage industry is one of the largest users of plastic chain plates. Hygiene is a critical concern in food processing, and plastic chain plates are ideal because they are easy to clean and do not react with food products. They can handle wet, dry, or greasy conditions without compromising performance.

Plastic chain plates are used in bakery lines, beverage bottling plants, meat processing units, and dairy production. Their non-corrosive properties ensure compliance with health and safety standards. They also support high-speed operations, enabling manufacturers to meet increasing production demands efficiently.

Use in Packaging Industry

Packaging lines require conveyors that can handle a variety of products with different shapes and weights. Plastic chain plates are widely adopted in this sector due to their ability to withstand wear and tear while providing smooth and consistent movement.

In packaging plants, plastic chain plates facilitate processes such as filling, labeling, sealing, and sorting. Their low-friction surface minimizes the risk of product damage, which is especially important for delicate items like glass bottles, cans, or packaged food products. Additionally, plastic chain plates allow for easy installation of modular systems, which can be expanded or reconfigured as production requirements change.

Automotive Manufacturing Applications

The automotive industry relies on plastic chain plates for efficient assembly lines. These plates are used in conveyor systems to transport car parts, engines, and other heavy components safely and efficiently. Plastic chain plates can endure high loads while maintaining smooth operation, reducing the risk of damage to expensive automotive components.

Moreover, the lightweight nature of plastic chain plates contributes to energy savings in extensive manufacturing facilities. They also reduce noise pollution in factories, creating a more comfortable and safer environment for workers. Plastic chain plates can be integrated with automated systems, enhancing precision and efficiency in modern automotive production.

Pharmaceutical and Medical Industry Applications

In pharmaceutical and medical manufacturing, cleanliness and precision are paramount. Plastic chain plates are particularly suited for these industries because they are resistant to chemicals and can be sanitized easily. They are used to transport medicines, medical devices, and packaging components in a controlled environment.

The smooth surface of plastic chain plates prevents the accumulation of dust and contaminants, ensuring product safety and compliance with strict hygiene regulations. Additionally, they can be designed to meet specific spacing and sizing requirements, making them ideal for handling delicate and high-value products in pharmaceutical production lines.

Electronics Manufacturing

The electronics industry benefits from the precision and reliability of plastic chain plates. These plates are used to convey electronic components, circuit boards, and finished devices through assembly lines. Their non-metallic composition prevents electrical interference, which is crucial in electronics manufacturing.

Plastic chain plates also allow for modular design in conveyor systems, making it easier to upgrade or modify production lines as technology evolves. Their low maintenance requirements and long service life reduce downtime and ensure consistent output, supporting high-tech manufacturing processes.

Chemical and Industrial Processing Applications

In chemical and industrial processing plants, resistance to harsh environments is essential. Plastic chain plates excel in these settings due to their resistance to corrosion, acids, and other chemicals. They are used in conveying systems for transporting raw materials, finished products, and packaging containers.

The durability of plastic chain plates allows them to withstand abrasive materials without significant wear. This reduces replacement costs and maintenance frequency. Their ability to operate in extreme temperatures and under heavy loads makes them ideal for demanding industrial applications.

Advantages in Automation and Smart Manufacturing

Plastic chain plates play a significant role in automation and smart manufacturing. Their modular design makes them compatible with automated systems, robotic handling, and conveyor integration. This allows manufacturers to streamline production processes, reduce manual labor, and increase overall efficiency.

In smart manufacturing environments, plastic chain plates support sensors and tracking systems for monitoring production flow and inventory. Their consistent and reliable operation ensures accurate timing and coordination in complex automated setups.

Sustainability and Environmental Benefits

Plastic chain plates also offer sustainability benefits. Many modern plastic chain plates are made from recyclable materials, reducing environmental impact. Their long lifespan and low maintenance requirements contribute to reduced waste and energy consumption in manufacturing operations.

By replacing metal chains that require lubrication and frequent replacement, plastic chain plates minimize the use of oils and chemicals, further supporting eco-friendly manufacturing practices.

Conclusion

Plastic chain plates have become indispensable in modern manufacturing, offering a versatile solution for industries ranging from food and beverage to automotive, electronics, pharmaceuticals, and chemical processing. Their corrosion resistance, lightweight design, low maintenance, and adaptability make them a superior choice for efficient and hygienic material handling.

As manufacturing continues to evolve towards automation, high-speed production, and sustainability, plastic chain plates will remain a critical component in ensuring smooth operations, product safety, and operational efficiency. Manufacturers adopting plastic chain plates benefit from reduced operational costs, increased productivity, and a more environmentally responsible production process.