Understanding the Importance of Galvanized Sheet

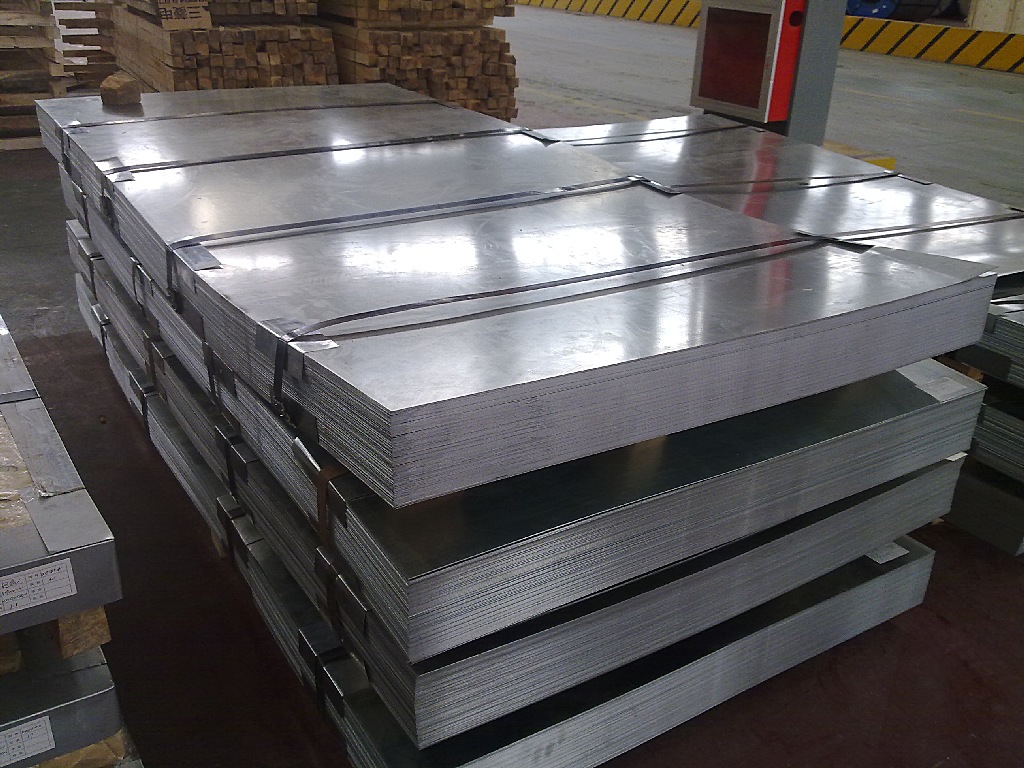

Galvanized sheet has become an essential material across multiple industries because of its unmatched ability to resist corrosion and maintain structural integrity over time. Whether it is used in construction, automotive manufacturing, or household appliances, galvanized sheet offers durability that meets demanding environmental conditions. For businesses like ahanjam, which focus on providing high-quality metal materials, understanding the vital role of galvanized sheet helps meet customer needs for longevity and reliability. Galvanization significantly enhances the lifespan of steel by applying a protective zinc coating that forms an effective barrier against moisture, oxygen, chemicals, and other corrosive elements. This process ensures that the base metal remains strong and unaffected even when exposed to challenging climates or industrial environments. As industries continue to shift toward long-lasting and cost-effective materials, the demand for galvanized sheet steadily increases https://ahanjam.com/%d9%88%d8%b1%d9%82-%da%af%d8%a7%d9%84%d9%88%d8%a7%d9%86%db%8c%d8%b2%d9%87/.

How Galvanization Improves Durability

The galvanization process involves immersing steel sheets into molten zinc, a method known as hot-dip galvanizing. The zinc reacts with the steel to form intermetallic layers that are tightly bonded to the surface. These layers create a robust protective shield that is difficult to penetrate, making galvanized sheet an ideal choice for applications that require extra strength. One of the major reasons companies like ahanjam rely heavily on galvanized sheet is the extended service life it provides. While untreated steel can degrade quickly in humid or salty environments, galvanized steel can withstand these conditions for decades. The zinc coating corrodes at a much slower rate than the steel underneath, allowing the base metal to stay intact even when exposed to harsh elements. This self-sacrificing quality of zinc means the coating protects the underlying steel until it is entirely consumed, ensuring long-term durability. Another key benefit is its resistance to abrasion and mechanical damage. The metallurgical bond between zinc and steel is extremely strong, making the surface more resistant to wear and tear. This added toughness is especially useful in construction sites, transportation vehicles, and manufacturing facilities where heavy usage is common.

Corrosion Resistance: The Key Advantage of Galvanized Sheet

Corrosion is the biggest enemy of steel, leading to structural weakness, safety hazards, and costly repairs. Galvanized sheet offers a reliable solution by forming a protective zinc carbonate layer when exposed to the environment. This layer effectively seals the surface from corrosive agents, preventing rust formation. Industries that operate in coastal regions, chemical plants, agricultural settings, and high-moisture environments heavily depend on this property to ensure long-lasting performance. Another notable advantage is the cathodic protection offered by zinc. Even if the coating is scratched or damaged, the zinc continues to protect the steel around the affected area by corroding first. This self-healing property ensures that small imperfections or impact damage do not compromise the entire sheet. For organizations such as ahanjam that prioritize quality and reliability, the corrosion-resistant nature of galvanized sheet is one of the main reasons it remains a preferred material for many clients. In addition, the protective layer also limits exposure to chemical reactions that could weaken steel. Whether the sheet is used in roofing, fencing, duct systems, or machinery, the corrosion-resistant coating helps maintain its structural strength over time. By slowing the oxidation process significantly, galvanized sheet ensures safety, performance, and reduced maintenance costs.

Applications That Benefit from Galvanized Sheet

Galvanized sheet has a wide range of uses due to its durability, cost-effectiveness, and resistance to environmental damage. In the construction industry, it is commonly used for roofing sheets, wall panels, framing structures, electrical conduits, and ventilation ducts. These applications require materials that can withstand weather fluctuations, moisture exposure, and mechanical stress, making galvanized sheet an excellent choice. The automotive industry also relies on galvanized sheet to manufacture car bodies, underframes, and other components that must endure road salt, water, and extreme temperatures. The enhanced corrosion resistance ensures that vehicles maintain their structural integrity and appearance for years. In addition, galvanized sheet is widely used in agriculture for silos, animal enclosures, storage units, and irrigation systems, as these environments often involve high humidity and chemical exposure. Manufacturing sectors benefit from galvanized sheet for producing appliances, industrial equipment, and storage containers that require durability and long service life. Businesses like ahanjam ensure that customers from all these industries have access to high-grade galvanized material that delivers consistent performance.

Economic Benefits of Using Galvanized Sheet

One of the main reasons galvanized sheet is preferred in so many industries is its cost-effectiveness. Although the initial price may be slightly higher than untreated steel, the long-term savings are significant. The reduced need for repairs, replacement, and maintenance makes galvanized sheet a more economical option over its lifespan. This is especially valuable for large-scale projects where long-term durability translates to substantial financial advantages. The long lifespan also means fewer disruptions caused by corrosion-related failures. Infrastructure built with galvanized sheet tends to remain sturdy and reliable, reducing safety concerns and prolonging the value of the investment. For suppliers like ahanjam, offering galvanized sheet ensures clients get a material that provides excellent value while maintaining strong structural performance. Another economic benefit is its recyclability. Galvanized sheet is 100% recyclable without losing its strength or quality, making it an environmentally friendly choice. This sustainability factor adds to its appeal for industries seeking greener solutions.

Why Galvanized Sheet Remains a Preferred Material

The combination of durability, corrosion resistance, and long-term cost savings makes galvanized sheet one of the most dependable materials available today. Its ability to withstand challenging environments and maintain structural integrity makes it essential in construction, manufacturing, transportation, and agricultural applications. By providing protection against rust, moisture, and chemical reactions, galvanized sheet ensures that buildings, vehicles, and machinery remain safe and functional. Businesses like ahanjam recognize these advantages and continue supplying high-quality galvanized materials to meet growing industry demands. The increasing focus on sustainability and durability further solidifies galvanized sheet as the material of choice for modern engineering and construction needs. Whether used in everyday structures or industrial systems, galvanized sheet offers unmatched reliability and long-term performance, making it an invaluable asset in environments where strength and protection are essential.